Hey there! As a supplier of flanged ball valves, I often get asked about the difference between standard and custom-made flanged ball valves. So, I thought I'd write this blog to break it down for you.

What's a Standard Flanged Ball Valve?

A standard flanged ball valve is like the off-the-shelf option you'd find in many hardware stores or valve catalogs. These valves are mass-produced according to well-established industry standards. For example, they might follow standards set by organizations like the American National Standards Institute (ANSI) or the Deutsches Institut für Normung (DIN).

One of the biggest advantages of standard flanged ball valves is their availability. Since they're mass-produced, you can usually get your hands on them pretty quickly. They're also generally more affordable because of the economies of scale in manufacturing. If you have a common application, like a basic water supply system in a commercial building, a standard valve will likely do the job just fine.

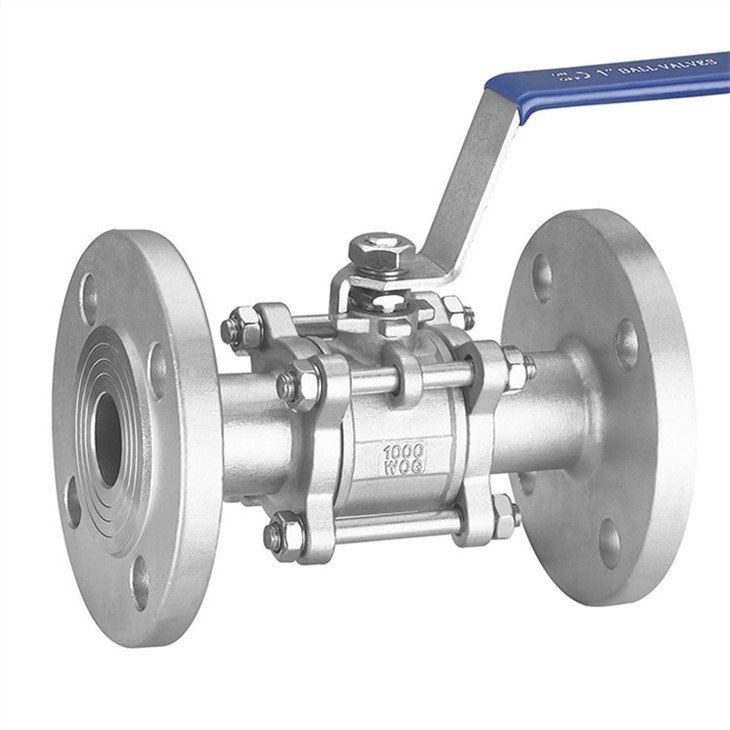

Let's talk about some of the common types of standard flanged ball valves you might come across. There's the Ss Flanged Ball Valve, which is made of stainless steel. Stainless steel is great because it's corrosion-resistant, so it can be used in a variety of environments, including those with a lot of moisture or chemicals.

Then there's the Din Flanged Ball Valve. The DIN standard is widely used in Europe and many other parts of the world. These valves are known for their high quality and precision engineering.

Another popular option is the Stainless Steel Flanged Ball Valve. Just like the Ss Flanged Ball Valve, it offers excellent corrosion resistance, making it suitable for applications in industries such as food and beverage, pharmaceuticals, and chemical processing.

What's a Custom-Made Flanged Ball Valve?

On the other hand, a custom-made flanged ball valve is designed and manufactured to meet specific requirements. Maybe you have a unique application that requires a valve with a non-standard size, material, or operating mechanism. That's where a custom valve comes in.

Let's say you're working on a project in a harsh environment where standard materials won't hold up. You might need a valve made of a special alloy that can withstand extreme temperatures and pressures. Or perhaps you need a valve with a specific flow rate or connection type that isn't available in standard models.

Custom-made flanged ball valves offer a lot of flexibility. You can get exactly what you need, tailored to your project's unique specifications. However, this flexibility comes at a cost. Custom valves usually take longer to produce because they require more design and engineering work. They're also generally more expensive than standard valves.

Key Differences

Now that we've defined what standard and custom-made flanged ball valves are, let's take a closer look at the key differences between them.

1. Design and Specifications

Standard valves are designed to meet general industry requirements. They come in a limited range of sizes, materials, and configurations. For example, a standard flanged ball valve might be available in sizes from 1/2 inch to 12 inches, with a few different materials like stainless steel or carbon steel.

Custom valves, on the other hand, can be designed to any specification. You can choose the exact size, material, and operating mechanism you need. This means you can get a valve that's perfectly suited to your application, whether it's a small-scale project or a large industrial installation.

2. Cost

As I mentioned earlier, standard valves are generally more affordable. The mass production process allows manufacturers to keep costs down. Custom valves, on the other hand, require more resources and time to design and manufacture, so they're usually more expensive.

However, it's important to consider the long-term costs. If a standard valve doesn't meet your requirements and fails prematurely, you might end up spending more money on repairs and replacements in the long run. A custom valve, while more expensive upfront, could save you money in the long term by providing a more reliable and efficient solution.

3. Lead Time

Standard valves are readily available, so you can usually get them quickly. Most suppliers keep a stock of standard models, so you can place an order and have the valve delivered within a few days or weeks.

Custom valves, on the other hand, take longer to produce. The design and engineering process can take several weeks or even months, depending on the complexity of the project. Then there's the manufacturing time, which can also be significant. So, if you're on a tight schedule, a standard valve might be a better option.

4. Availability

Standard valves are widely available from many suppliers. You can find them in hardware stores, online marketplaces, and valve distributors. This means you have a lot of options when it comes to purchasing a standard valve.

Custom valves, on the other hand, are usually only available from specialized manufacturers. You'll need to find a supplier who has the expertise and capabilities to design and manufacture a custom valve for you. This can limit your options, but it also ensures that you're working with a company that knows what they're doing.

Which One Should You Choose?

So, how do you decide whether to go with a standard or custom-made flanged ball valve? It really depends on your specific needs and circumstances.

If you have a common application that can be met with a standard valve, then that's probably the way to go. Standard valves are affordable, readily available, and easy to install. They're a great option for most general-purpose applications.

However, if you have a unique application that requires a valve with specific specifications, then a custom valve is the better choice. It might cost more and take longer to produce, but it will provide a more reliable and efficient solution in the long run.

Conclusion

In conclusion, both standard and custom-made flanged ball valves have their advantages and disadvantages. As a supplier, I can help you determine which type of valve is best for your project. Whether you need a standard valve for a quick and easy installation or a custom valve for a complex application, I've got you covered.

If you're interested in learning more about our flanged ball valves or discussing your project requirements, don't hesitate to reach out. We're here to help you find the right valve for your needs.

References

- Valve Handbook, by J. S. Keenan

- Industrial Valves: Selection and Sizing, by R. A. Brown